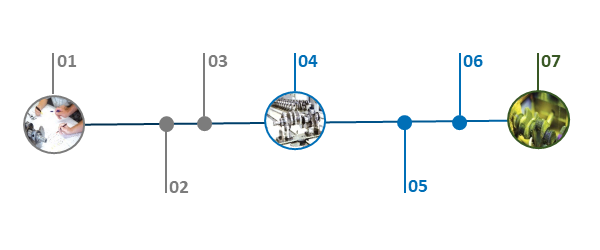

Processes

We combine various manufacturing technologies to produce high-precision and complex crankshafts and conrods. Our many years of experience and our ultramodern CNC machines mean that we can accompany you from the development stage through to the final product.

- Advice, product development and construction

No matter whether you need a series, a small number of pieces, parts for special fields of use or prototypes: after advising our customers, we plan and build individual crankshafts and conrods – quickly, flexibly and efficiently. - Milling and turning

The journals are machined and brought into shape by two tools on our CNC millers. - Drilling

Precise holes are drilled to match the surface requirements depending on the specifications and customer’s wishes. - Grinding

Modern grinding machines guarantee high-precision ground crankshafts and conrods. - Cleaning

All of our products are cleaned in industrial washing plants according to the necessary component cleanliness. - Superfinish/Bandfinish

The final precision treatment of the surfaces is carried out on automatic Superfinish machines. This guarantees the necessary surface requirements and high-precision dimensional tolerances. - Quality assurance

We measure and check all parts to make sure they are 100 percent. We can also mark the crankshafts and conrods by means of data-matrix-codes to guarantee their safe identification and tracing at the customer’s request.